Beach erosion is a common challenge up and down Florida’s coastline. Shifting currents, tides, and structural engineering tend to accentuate the impacts of beach erosion and trigger problems—this is the case for the Florida Power and Light (FPL) St. Lucie Nuclear Power Plant, located beachside on Hutchinson Island, Florida. In 2004, Hurricane Frances caused severe erosion to the stretch of coast in front of the plant, resulting in the loss of around 70 feet of beach. With this significant barrier of beach sediment removed, ocean waves were able to reach within 20 feet of the power plant’s water discharge canal.

In a 2020 pilot project to improve beach erosion conditions FPL deployed an experimental breakwater made up of 580 concrete reef balls, all four feet in height. Unlike traditionally engineered breakwaters that can negatively impact aquatic species and produce secondary erosion channels, the reef mats were made to replicate the substrate of a natural reef. Designed to serve two specific purposes, to both decrease wave energy and therefore reduce beach erosion and to create a healthy coastal reef habitat, this artificial reef was installed with nature in mind.

Reef balls are made to safeguard against storm energy—like the Cat 3 cyclonic forces imparted by Hurricane Frances—while also allowing endangered native species like sea turtles access to a nesting beach. The 3D structure created by the reef balls are hot spots for microorganism settlement, fish aggregation, corals, and other aquatic species. Additionally, since sediment can travel through the series of concrete reef balls, there is hope for sediment accumulation on the beach face.

Paving the Way

While artificial reefs made with reef balls are common mitigation tactics used around the world, they are found in smaller numbers along the East Coast of the United States in the Atlantic. While knowledge from other locations with similar erosional and habitat issues, like on coastlines along the Gulf of Mexico, can serve as baseline knowledge, there are not many direct comparable research projects in the Atlantic. This pilot project, while serving a specific mitigation purpose, can also be used for understanding the success and efficacy of this solution for others.

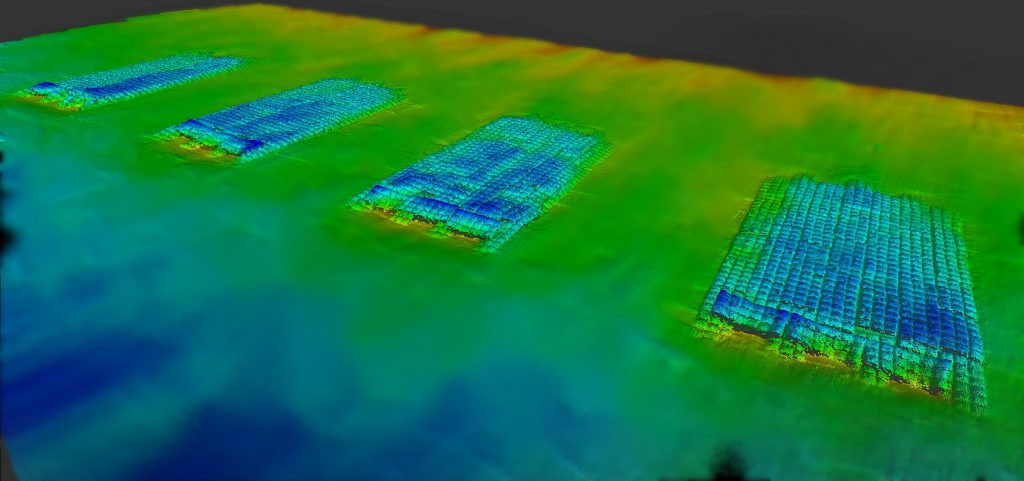

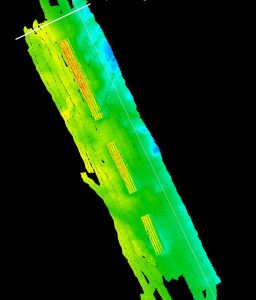

The reef balls were deployed off the beach east of the FPL power plant to decrease beach erosion and provide habitat. (Image credit: M&E)

Morgan & Eklund (M&E), contracted by Florida Power and Light, was tasked with completing a hardbottom survey pre- and post-project completion. The hardbottom survey provided accurate, validated data to guide engineers and scientists to complete the reef mat deployment safely and efficiently.

The Right Tools

When performing an accurate survey of this nature, the field teams at M&E rely on a number of key technologies—including side scan sonar, LiDAR, RTK GPS, and multibeam echo sounders—but instrumental to this particular project was the deployment of M&E’s autonomous survey vehicle (ASV). Our current ASV of choice is a SeaRobotics SR-Surveyor M1.8, capable of operating a suite of sensors that simultaneously measure the depth and size of a body of water, map its physical characteristics, and identify unique attributes or obstructions. The ASV’s capacity to capture such a diverse range of data sets simultaneously (two frequencies of side scan, motion tolerant side scan, wide swath bathymetry, backscatter, LiDAR point cloud data, and discharge data) alongside its portability and ease of deployment (fully integrated sensor suite in a 1.8 meter package) deliver a series of game-changing benefits to M&E operators, and so subsequently our customers:

- Cost-effective survey operations: The deployment of ASVs reduces the need for additional topside support.

- Precision and accuracy: The automation of survey operations removes the margin of human error.

- Safety in marine robotics: ASVs remove personnel from potentially hazardous waters and grant access to restricted waters—waters that traditional survey vessels cannot navigate.

- Speed of data processing and interpretation: Depending on the survey in question, data can be managed in real time from a shore-based command or a workboat.

For this project in particular, the needed operating depth for a traditional surveying vessel was impeded by the reef balls. The ASV was able to go where the survey vessel could not and maneuver efficiently and accurately to produce the needed data set for FPL.

A 3D surface generated from data obtained by M&E’s ASV. (Image credit: M&E)

Following the deployment in July 2020, M&E will complete periodic monitoring surveys to help decipher erosional changes along the beach as well as bathymetry changes in and surrounding the reef mats. In addition to M&E’s monitoring, InWater Research Group provides environmental monitoring of the reef area, more specifically as it pertains to impacts on sea turtles, to assess for habitat impacts and bioproductivity.

Overall, research pilot projects like this one help provide data and a foundation for applied marine science practitioners to employ mitigative tactics to solve erosion and habitat problems.

This feature appeared in Environment, Coastal, and Offshore (ECO) Magazine’s 2023 Marine Environmental Research Deep Dive 2 special edition, to read more access the magazine here.